Devgiri Forgings / Infrastructure / Facility

Facility

Nidec CNC Hobbing Machines

The recent addition of 8 fully automated machines, which includes three units of model GE200 and five units of model GE150, each equipped with inbuilt chamfering functionality to our Production lines. These machines are 4-station models, enhancing our manufacturing efficiency and precision in gear production.

Automated Sealed Quench Furnaces (Epson Make)

Our advanced heat treatment infrastructure features five fully automated Sealed Quench Furnaces, each with a capacity of 1500 kg per batch, ensuring precision and consistency in every cycle. The setup is further supported by dedicated Pre-Post Washing systems and Tempering & Preheating units, enabling us to deliver high-quality, performance-driven components tailored to diverse industrial needs.

CNC Hard Part Turning Machines

Our machining capabilities are strengthened by a fleet of six fully automated Muratec CNC Turning Centers, featuring MW200EX and MW120EX models. Designed for high precision, these machines support components up to 200 mm in diameter and are equipped with gantry automation and in-process auto gauging, ensuring consistent quality and efficiency across high-volume production.

Gear Grinding

Blank Turning & Gun Drilling

Facing & centering + Battery of turning centers covering the product range of dia up to 300 mm and length upto 1500 mm.

Devgiri introduced Multispindle Gun drilling wherein parts can be drilled from 4mm to 32mm and length upto 500mm.

Gear Manufacturing

Gears and shafts are produced with battery of existing 16 No’s Mitsubishi CNC Hobbing Machines

- Between centre – 1000 mm

- Multi Hobbing feature

- High speed

- Maximum Gear dia-250mm

- Dry and wet cutting

Gear module 1 to 9, shafts upto length 1500mm

Conventional hobbing machines, Shaving machines, Shaping machines, Tooth Chamfering & Rounding, Deburring machines

Heat Treatment

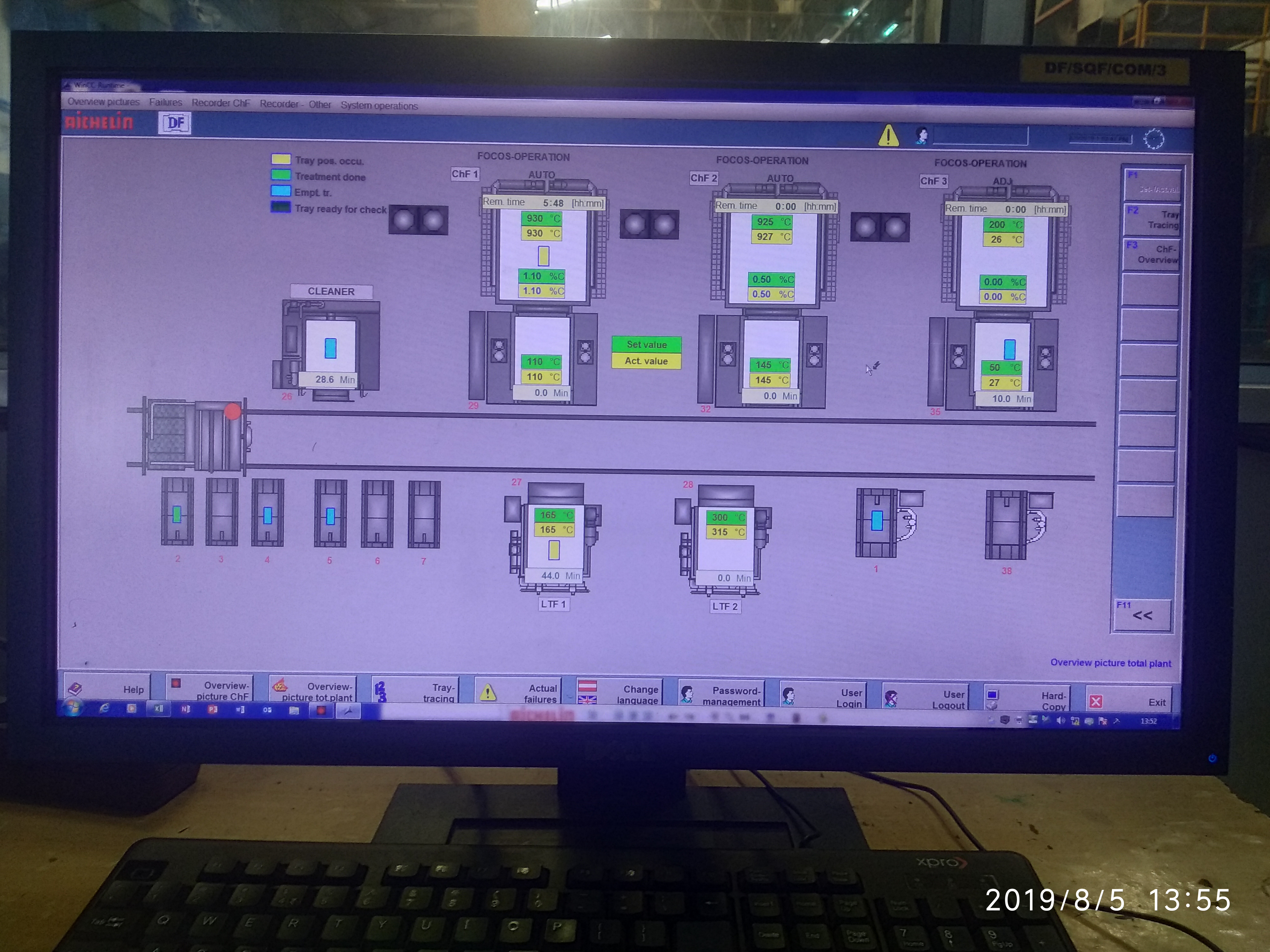

Seal Quenched Furnaces

- Focus 2 Controlled. No manual intervention up to 6 nos. of charges

- Online diffusion and auto cycle correction

- Recipe preparation and simulation

- Laser sensors to enable fully automatic mode

- Fully automatic loading and unloading

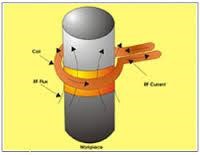

Induction Hardening

- Available with high /medium /low frequency

- 75 Kw/1000 mm from HF Power

- 100 Kw/1000 mm from HF Power

- 300 Kw/1500 mm from HF Power

- Tempering Furnace for stress relieving operation

Automatic Shaft Straightening

- This machine from Towa Seiki, Japan can automatically straighten shafts up to 1000mm

- No manual intervention required

- Comes with an Accept reject system

- Acoustic automatic crack detection system present

Gear module 1 to 9, shafts upto length 1500mm

Conventional hobbing machines, Shaving machines, Shaping machines, Tooth Chamfering & Rounding, Deburring machines

Gear Grinding

Devgiri Forging has collection of Liebherr and Samputensili machines for its Gear Grinding process.

Features of Liebherr LC300

- On this machine Gears can be Ground by Generating & Profile Grinding

- Can equally use Ceramic Gear Grinding Worm wheels & form wheels & Electroplated CBN Worm wheels & Profile Discs

- Dynamic balancing of Gear Grinding wheels

- Easy & Fast changeover of Grinding Fixtures , Grinding wheels

- Twist Free Grinding

- Shoulder Gear Grinding with Generating Gear Grinding by use of Grinding Wheel Dia upto 90 mm

- Contour Dressing

- Internal splines can be ground for more than 110 mm minor dia

- External Straight Splines can also be Ground

Features of Samputensili G450

- On this machine Gears can be Ground by Generating & Profile Grinding

- Can equally use Worm wheels & form wheels both in ceramic & electroplated CBN

- Can Grind the Gear & Achieve Din Class 4

- Dynamic balancing of Gear Grinding wheels

- Easy & Fast Change over- Grinding wheel with Standard HSK, Hydraulic Clamping of Grinding Disc, Clamping Fixture with Standard ASA cone & Pulling System

- Work Table rotates +45°/-45° for easy & ergonomic access

Devgiri Forging has a battery of CNC Grinding & Conventional Grinding Machines for angular & plunge type grinding, supported by Lapping machines for super finishing operations.

Between centre – Max 1100mm

Diameter- Max 180 mm

In-process gauging with Tespa / Marposs & final inspection with roughness testers

Liebherr

Samputensili